>> TSUBAKI POWER - LOCK KE Series

Features

-

Range of Size Available

Available in a variety of size for smaller motors or sensors.

-

Wide Tolerance for Shafts

POWER-LOCK KE Series is designed with a slit construction and special taper angle to cover a wider tolerance of shaft szies, such as motor shafts.

-

Self - Centering

-

Compact Construction

Compact design is possible, because the ratio of inside and outside diameter is small.

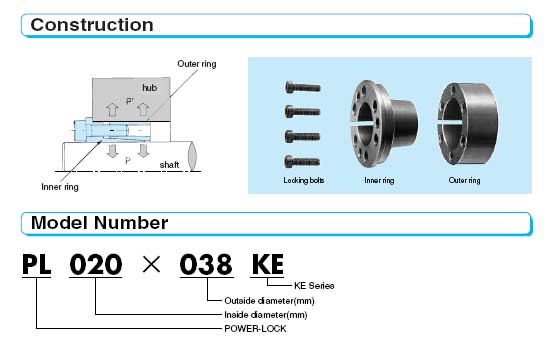

Model Number |

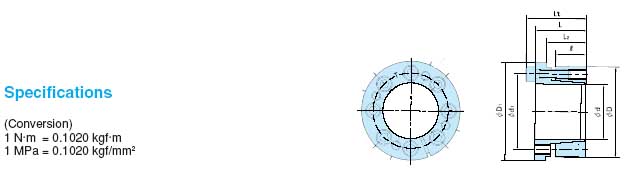

Dimensions (mm) |

Transmissible Torque |

Transmissible Thrust |

Contact Pressure (MPa) |

Locking Bolts |

Mass |

|||||||||||||

d x D Inside Dia Outside Dia |

L2 |

L |

Lt |

d1 |

D1 |

Mt |

Pax |

Shaft P |

Hub bore P' |

Qty. |

Size |

Tightening Torque Ma |

|||||||

N-m |

{kgf-m} |

kN |

{kgf} |

MPa |

{kgf/mm2} |

MPa |

{kgf/mm2} |

N.m |

{kgf.m} |

(kg) |

|||||||||

PL005x 016KE |

8 |

12 |

13.5 |

16.5 |

11.5 |

18.5 |

7.5 |

{ 0.77} |

2.86 |

{292} |

223 |

{22.8} |

70 |

{7.1} |

3 |

M3x10 |

1.9 |

{0.19} |

0.02 |

PL006x 017KE |

8 |

12 |

13.5 |

16.5 |

12.5 |

19.5 |

9.0 |

{0.92} |

2.86 |

{292} |

186 |

{19.0} |

66 |

{6.7} |

3 |

M3x10 |

1.9 |

{0.19} |

0.02 |

PL008x 021KE |

10 |

14.5 |

16.5 |

20.5 |

15.6 |

23.5 |

24.5 |

{2.5} |

5.96 |

{608} |

232 |

{23.7} |

88 |

{9.0} |

3 |

M4x12 |

4.8 |

{0.49} |

0.03 |

PL010x 23KE |

10 |

14.5 |

16.5 |

20.5 |

17.6 |

25.5 |

31.4 |

{3.2} |

5.96 |

{608} |

186 |

{19.0} |

80 |

{8.2} |

3 |

M4x12 |

4.8 |

{0.49} |

0.04 |

PL011x024KE |

10 |

14.5 |

16.5 |

20.5 |

18.6 |

26.5 |

34.3 |

{3..5} |

5.96 |

{608} |

169 |

{17.2} |

70 |

{7.9} |

3 |

M4x12 |

4.8 |

{0.49} |

0.04 |

PL012x026KE |

10 |

14.5 |

16.5 |

20.5 |

20 |

28.5 |

50.0 |

{5.1} |

7.94 |

{810} |

207 |

{21.1} |

95 |

{9.7} |

4 |

M4x12 |

4.8 |

{0.49} |

0.05 |

PL014x028KE |

12 |

17.5 |

20 |

24 |

22 |

30.5 |

73.5 |

{7.5} |

9.90 |

{1010} |

184 |

{18.8} |

92 |

{9.4} |

5 |

M4x14 |

4.8 |

{0.49} |

0.06 |

PL015x029KE |

12 |

17.5 |

20 |

24 |

23 |

31.5 |

94.1 |

{9.6} |

11.9 |

{1210} |

207 |

{21.1} |

107 |

{10.9} |

6 |

M4x14 |

4.8 |

{0.49} |

0.07 |

PL016x030KE |

12 |

17.5 |

20 |

24 |

24 |

32.5 |

101 |

{10.3} |

11.9 |

{1210} |

194 |

{19.8} |

103 |

{10.5} |

6 |

M4x14 |

4.8 |

{0.49} |

0.07 |

PL 017x031KE |

12 |

17.5 |

20 |

24 |

25 |

33.5 |

107 |

{10.9} |

11.9 |

{1210} |

182 |

{18.6} |

100 |

{10.2} |

6 |

M4x14 |

4.8 |

{0.49} |

0.07 |

PL018 x032KE |

12 |

17.5 |

20 |

24 |

26 |

34.5 |

113 |

{11.5} |

11.9 |

{1210} |

172 |

{17.6} |

97 |

{9.9} |

6 |

M4x14 |

4.8 |

{0.49} |

0.08 |

PL 019x033KE |

12 |

17.5 |

20 |

24 |

27 |

35.5 |

120 |

{12.2} |

11.9 |

{1210} |

163 |

{16.6} |

94 |

{9.6} |

6 |

M4x14 |

4.8 |

{0.49} |

0.08 |

PL 020x038KE |

15 |

20.5 |

25 |

30 |

30 |

42 |

206 |

{21.0} |

19.4 |

{1980} |

203 |

{20.7} |

107 |

{10.9} |

6 |

M5x18 |

9.8 |

{1.0} |

0.14 |

PL 022x040KE |

15 |

20.5 |

25 |

30 |

32 |

44 |

226 |

{23.1} |

19.4 |

{1980} |

184 |

{18.8} |

101 |

{10.3} |

6 |

M5x18 |

9.8 |

{1.0} |

0.15 |

PL024x042KE |

15 |

20.5 |

25 |

30 |

34 |

46 |

329 |

{33.6} |

25.9 |

{2640} |

225 |

{23.0} |

128 |

{13.1} |

8 |

M5x18 |

9.8 |

{1.0} |

0.16 |

PL025x043KE |

15 |

20.5 |

25 |

30 |

35 |

47 |

343 |

{35.0} |

25.9 |

{2640} |

216 |

{22.0} |

125 |

{12.8} |

8 |

M5x18 |

9.8 |

{1.0} |

0.17 |

PL 028x046KE |

17 |

22.5 |

28 |

33 |

38.5 |

50 |

432 |

{44.1} |

29.2 |

{2980} |

191 |

{19.5} |

117 |

{11.9} |

9 |

M5x18 |

9.8 |

{1.0} |

0.21 |

PL030x048KE |

17 |

22.5 |

28 |

33 |

40.5 |

52 |

515 |

{52.5} |

32.4 |

{3310} |

199 |

{20.3} |

124 |

{12.7} |

10 |

M5x18 |

9.8 |

{1.0} |

0.22 |

PL032x050KE |

17 |

22.5 |

28 |

33 |

42.5 |

54 |

549 |

{56.0} |

32.4 |

{3310} |

186 |

{19.0} |

120 |

{12.2} |

10 |

M5x18 |

9.8 |

{1.0} |

0.23 |

PL035x057KE |

19 |

25 |

32 |

38 |

47.5 |

62 |

678 |

{69.2} |

36.6 |

{3730} |

172 |

{17.5} |

106 |

{10.8} |

8 |

M6x22 |

16.7 |

{1.7} |

0.36 |

PL038x060KE |

19 |

25 |

32 |

38 |

50.5 |

65 |

921 |

{94.0} |

45.8 |

{4670} |

198 |

{20.2} |

125 |

{12.8} |

10 |

M6x22 |

16.7 |

{1.7} |

0.39 |

PL040x062KE |

19 |

25 |

32 |

38 |

52.5 |

67 |

969 |

{98.9} |

45.8 |

{4670} |

188 |

{19.2} |

122 |

{12.4} |

10 |

M6x22 |

16.7 |

{1.7} |

0.40 |

PL042x064KE |

19 |

25 |

32 |

38 |

54.5 |

69 |

1010 |

{103} |

45.8 |

{4670} |

179 |

{18.3} |

118 |

{12.0} |

10 |

M6x22 |

16.7 |

{1.7} |

0.42 |

PL045x067KE |

19 |

25 |

32 |

38 |

57.5 |

72 |

1090 |

{111} |

45.8 |

{4670} |

168 |

{17.1} |

113 |

{11.5} |

10 |

M6x22 |

16.7 |

{1.7} |

0.44 |

PL048x070KE |

19 |

25 |

32 |

38 |

60.5 |

75 |

1390 |

{142} |

54.9 |

{5600} |

188 |

{19.2} |

129 |

{13.2} |

12 |

M6x22 |

16.7 |

{1.7} |

0.46 |

PL050x072KE |

19 |

26 |

34.5 |

40.5 |

63.5 |

77 |

1700 |

{173} |

64.1 |

{6540} |

211 |

{21.5} |

146 |

{14.9} |

14 |

M6x25 |

16.7 |

{1.7} |

0.50 |

PL055x077KE |

19 |

26 |

34.5 |

40.5 |

67.5 |

82 |

1860 |

{190} |

64.1 |

{6540} |

191 |

{19.5} |

137 |

{14.0} |

14 |

M6x25 |

16.7 |

{1.7} |

0.55 |

PL060x082KE |

19 |

26 |

34.5 |

40.5 |

72.5 |

87 |

2180 |

{222} |

68.6 |

{7000} |

188 |

{19.2} |

137 |

{14.0} |

15 |

M6x25 |

16.7 |

{1.7} |

0.59 |

PL065x087KE |

19 |

26 |

34.5 |

40.5 |

77.5 |

92 |

2360 |

{241} |

68.6 |

{7000} |

173 |

{17.7} |

129 |

{13.2} |

15 |

M6x25 |

16.7 |

{1.7} |

0.63 |

PL070x097KE |

22 |

31.5 |

40.5 |

48.5 |

85.5 |

102 |

3750 |

{383} |

101 |

{10300} |

206 |

{21.0} |

148 |

{15.1} |

12 |

M6x25 |

40.2 |

{4.1} |

0.99 |

PL075x102KE |

22 |

31.5 |

40.5 |

48.5 |

90.5 |

107 |

4030 |

{411} |

101 |

{10300} |

192 |

{19.6} |

141 |

{14.1} |

12 |

M8x30 |

40.2 |

{4.1} |

1.05 |

PL080x107KE |

22 |

31.5 |

41.5 |

49.5 |

95.5 |

112 |

5010 |

{511} |

118 |

{12000} |

210 |

{21.4} |

157 |

{16.0} |

14 |

M8x30 |

40.2 |

{4.1} |

1.14 |

PL085x112KE |

22 |

31.5 |

41.5 |

49.5 |

100.5 |

117 |

5320 |

{543} |

118 |

{12000} |

198 |

{20.2} |

150 |

{15.3} |

14 |

M8x30 |

40.2 |

{4.1} |

1.20 |

PL090x123KE |

29 |

41.5 |

54 |

64 |

109.5 |

128 |

8960 |

{914} |

187 |

{19100} |

224 |

{22.9} |

165 |

{16.8} |

14 |

M10x40 |

81.3 |

{8.3} |

2.08 |

PL095x128KE |

29 |

41.5 |

54 |

64 |

114.5 |

133 |

9460 |

{965} |

187 |

{19100} |

213 |

{21.7} |

158 |

{16.1} |

14 |

M10x40 |

81.3 |

{8.3} |

2.18 |

PL100x133KE |

29 |

41.5 |

54 |

64 |

119.5 |

138 |

9900 |

{1010} |

187 |

{19100} |

203 |

{20.7} |

152 |

{15.5} |

14 |

M10x40 |

81.3 |

{8.3} |

2.28 |

Note :-

- Torque Mt in above table is shown in case of Pax =0 and thrust is shown in case of Mt =0. When torque and thrust are applied, calculate composite torque and compare it with Mt.

-

Contact pressure P and P' in the above table indicate mean value only.

These pressures will fluctuate from - 20% to +40% due to the variable friction component forces resulting from the locking bolts. Mt and Pax are calculated as minimum values.