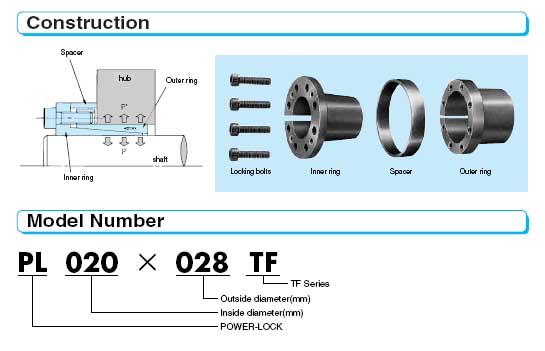

>> TSUBAKI POWER - LOCK TF Series

Features

-

Small-diameter hub can be connected

POWER-LOCK TF is designed for small diameter hub. Outside diameter of POWER-LOCK and contact pressure in the hub bore are small.

-

Self- Centering

The TF Series has excellent centering function Pre-centering (guide) is not required.

-

Simple construction

Model Number |

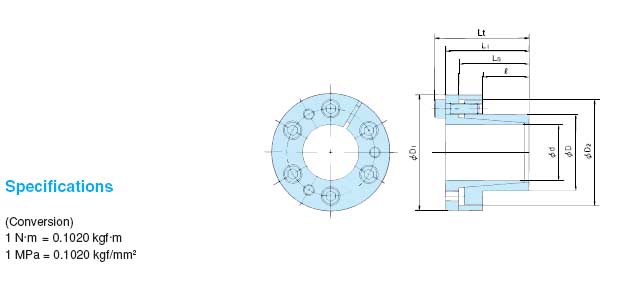

Dimensions (mm) |

Transmissible Torque |

Transmissible Thrust |

Contact Pressure |

Locking Bolts |

Mass |

|||||||||||||

d x D Inside Dia Outside Dia |

Mt |

Pax |

Shaft P |

Hub bore P' |

Qty |

Size |

Tightening Torque Ma |

||||||||||||

L0 |

L1 |

Lt |

D1 |

D2 |

N-m |

{kgf.m} |

kN |

{kgf} |

MPa |

{kgf/mm2} |

MPa |

{kgf/mm2} |

N.m |

{kgf.m} |

(kg) |

||||

PL006x012TF |

10 |

19 |

21 |

24 |

25 |

23.0 |

11 |

{1.2} |

3.78 |

{386} |

186 |

{19.0} |

93 |

{9.5} |

3 |

M3 x 10 |

2.25 |

{0.23} |

0.05 |

PL008x015 TF |

12 |

22 |

25 |

29 |

27 |

24.0 |

26 |

{2.7} |

6.53 |

{666} |

200 |

{20.4} |

107 |

{10.9} |

3 |

M4 x 10 |

4.80 |

{0.49} |

0.07 |

PL010x018TF |

14 |

23 |

26 |

30 |

32 |

28.0 |

44 |

{4.4} |

8.70 |

{888} |

183 |

{18.7} |

102 |

{10.4} |

4 |

M4 x 10 |

4.80 |

{0.49} |

0.09 |

PL011x018TF |

14 |

23 |

26 |

30 |

32 |

28.0 |

48 |

{4.9} |

8.70 |

{888} |

167 |

{17.0} |

102 |

{10.4} |

4 |

M4 x 10 |

4.80 |

{0.49} |

0.08 |

PL012x020TF |

14 |

23 |

26 |

30 |

34 |

30.0 |

52 |

{5.3} |

8.70 |

{888} |

153 |

{15.6} |

92 |

{9.3} |

4 |

M4 x 10 |

4.80 |

{0.49} |

0.10 |

PL014x022TF |

14 |

23 |

26 |

30 |

38 |

33.0 |

61 |

{6.2} |

8.70 |

{888} |

131 |

{13.4} |

83 |

{8.5} |

4 |

M4 x 10 |

4.80 |

{0.49} |

0.12 |

PL015x023TF |

14 |

24 |

30 |

35 |

39 |

35.5 |

107 |

{10.9} |

14.2 |

{1450} |

199 |

{20.4} |

130 |

{13.3} |

4 |

M5 x 14 |

9.80 |

{1.00} |

0.15 |

PL016x024TF |

14 |

24 |

30 |

35 |

40 |

36.5 |

114 |

{11.6} |

14.2 |

{1450} |

187 |

{19.1} |

125 |

{12.7} |

4 |

M5 x 14 |

9.80 |

{1.00} |

0.16 |

PL018x026TF |

18 |

31 |

38 |

44 |

47 |

42 |

196 |

{20} |

21.6 |

{2200} |

217 |

{22.1} |

126 |

{12.9} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.27 |

PL019x027TF |

18 |

31 |

38 |

44 |

49 |

43 |

206 |

{21} |

21.6 |

{2200} |

205 |

{20.9} |

122 |

{12.4} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.29 |

PL020x028TF |

18 |

31 |

38 |

44 |

50 |

44 |

216 |

{22} |

21.6 |

{2200} |

195 |

{19.9} |

118 |

{12.0} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.30 |

PL022x032TF |

25 |

38 |

45 |

51 |

54 |

48 |

245 |

{25} |

21.6 |

{2200} |

121 |

{12.3} |

74 |

{7.5} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.38 |

PL024x034TF |

25 |

38 |

45 |

51 |

56 |

50 |

265 |

{27} |

21.6 |

{2200} |

111 |

{11.3} |

70 |

{7.1} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.41 |

PL025x034TF |

25 |

38 |

45 |

51 |

56 |

50 |

274 |

{28} |

21.6 |

{2200} |

107 |

{10.9} |

70 |

{7.1} |

4 |

M6 x 18 |

16.7 |

{1.70} |

0.39 |

PL028x039TF |

25 |

38 |

45 |

51 |

61 |

55 |

461 |

{47} |

32.3 |

{3300} |

142 |

{14.5} |

91 |

{9.3} |

6 |

M6 x 18 |

16.7 |

{1.70} |

0.47 |

PL030x041TF |

25 |

38 |

45 |

51 |

62 |

57 |

500 |

{51} |

32.3 |

{3300} |

133 |

{13.6} |

86 |

{8.8} |

6 |

M6 x 18 |

16.7 |

{1.70} |

0.48 |

PL032x043FT |

25 |

38 |

45 |

51 |

65 |

59 |

529 |

{54} |

32.3 |

{3300} |

124 |

{12.7} |

82 |

{8.4} |

6 |

M6 x 18 |

16.7 |

{1.70} |

0.52 |

PL035x047FT |

32 |

45 |

52 |

58 |

69 |

62 |

774 |

{79} |

44.1 |

{4500} |

116 |

{11.8} |

78 |

{8.0} |

8 |

M6 x 18 |

16.7 |

{1.70} |

0.63 |

PL038x050FT |

32 |

45 |

52 |

58 |

72 |

66 |

843 |

{86} |

44.1 |

{4500} |

107 |

{10.9} |

74 |

{7.5} |

8 |

M6 x 18 |

16.7 |

{1.70} |

0.67 |

PL040x053TF |

32 |

45 |

52 |

58 |

75 |

69 |

882 |

{90} |

44.1 |

{4500} |

101 |

{10.3} |

70 |

{7.1} |

8 |

M6 x 18 |

16.7 |

{1.70} |

0.73 |

PL042x055FT |

32 |

45 |

52 |

58 |

78 |

71 |

931 |

{95} |

44.1 |

{4500} |

96 |

{9.8} |

68 |

{6.9} |

8 |

M6 x 18 |

16.7 |

{1.70} |

0.78 |

PL045x059FT |

45 |

62 |

70 |

78 |

86 |

80 |

1850 |

{189} |

82.3 |

{8400} |

119 |

{12.1} |

82 |

{8.4} |

8 |

M8 x 22 |

40.2 |

{4.10} |

1.23 |

PL048x062FT |

45 |

62 |

70 |

78 |

87 |

81 |

1970 |

{201} |

82.3 |

{8400} |

111 |

{11.3} |

78 |

{8.0} |

8 |

M8 x 22 |

40.2 |

{4.10} |

1.24 |

PL050x065FT |

45 |

62 |

70 |

78 |

92 |

86 |

2060 |

{210} |

82.3 |

{8400} |

107 |

{10.9} |

74 |

{7.6} |

8 |

M8 x 22 |

40.2 |

{4.10} |

1.40 |

PL055x071FT |

55 |

72 |

80 |

88 |

98 |

92 |

2550 |

{260} |

92.1 |

{9400} |

87 |

{8.9} |

63 |

{6.4} |

9 |

M8 x 22 |

40.2 |

{4.10} |

1.70 |

PL060x077FT |

55 |

72 |

80 |

88 |

104 |

98 |

2770 |

{283} |

92.1 |

{9400} |

80 |

{8.2} |

58 |

{5.9} |

9 |

M8 x 22 |

40.2 |

{4.10} |

1.90 |

PL065x084FT |

55 |

72 |

80 |

88 |

111 |

105 |

3010 |

{307} |

92.1 |

{9400} |

74 |

{7.6} |

53 |

{5.4} |

9 |

M8 x 22 |

40.2 |

{4.10} |

2.21 |

PL070x090FT |

65 |

86 |

96 |

106 |

1198 |

113 |

5150 |

{525} |

147 |

{15000} |

92 |

{9.4} |

67 |

{6.8} |

9 |

M10 x 25 |

81.3 |

{8.30} |

3.05 |

PL075x095TF |

65 |

86 |

96 |

106 |

126 |

119 |

5490 |

{560} |

147 |

{15000} |

86 |

{8.8} |

63 |

{6.4} |

9 |

M10 x 25 |

81.3 |

{8.30} |

3.32 |

PL080x100TF |

65 |

86 |

96 |

106 |

131 |

125 |

7840 |

{800} |

196 |

{20000} |

108 |

{11.0} |

79 |

{8.1} |

12 |

M10 x 25 |

81.3 |

{8.30} |

3.50 |

PL085x106TF |

65 |

86 |

96 |

106 |

137 |

131 |

8330 |

{850} |

196 |

{20000} |

101 |

{10.3} |

75 |

{7.7} |

12 |

M10 x 25 |

81.3 |

{8.30} |

3.81 |

PL090x112TF |

65 |

86 |

96 |

106 |

144 |

137 |

8820 |

{900} |

196 |

{20000} |

96 |

{9.8} |

72 |

{7.3} |

12 |

M10 x 25 |

81.3 |

{8.30} |

4.20 |

Note :-

- Torque Mt in above table is shown in case of Pax=0 and thrust Pax is shown n case of Mt=0 When torque and thrust are applied calculate composite torque and compare it with Mt.

-

Contact pressure P and P' in the above table indicate mean value only.

These pressures will fluctuate from - 20% to +40% due to the variable friction component forces resulting from the locking bolts. Mt and Pax are calculated as minimum values.