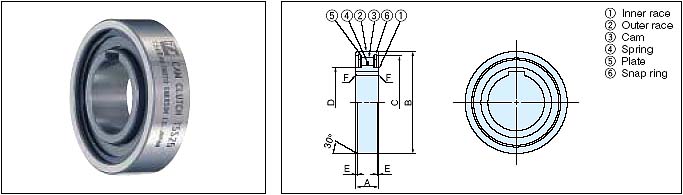

>> TSS SERIES CAM CLUTCH

Dimensions and Capacities

Dimensions in mm

Model |

Torque Capacity |

Max. Overruning Speed |

Drag Torque |

Bore Size |

Keyway |

A |

B |

C |

D |

E |

F |

Weight |

|

Inner Race |

Outer Race |

||||||||||||

N-m |

Ø min |

Ø min |

N-m |

H7 |

g |

||||||||

TSS 8 |

6.7 |

6000 |

3000 |

0.005 |

8 |

2 x 1.0 |

8 |

24 |

22.2 |

11.4 |

0.6 |

0.6 |

14 |

TSS 10 |

12 |

4500 |

2300 |

0.007 |

10 |

3 x 1.4 |

9 |

30 |

27 |

15.6 |

0.6 |

0.6 |

27 |

TSS 12 |

17 |

4000 |

2000 |

0.009 |

12 |

4 x 1.8 |

10 |

32 |

29.5 |

18 |

0.6 |

0.6 |

31 |

TSS 15 |

22 |

3500 |

1800 |

0.01 |

15 |

5 x 1.2 |

11 |

35 |

32 |

20.6 |

0.6 |

0.6 |

39 |

TSS 20 |

41 |

2600 |

1300 |

0.01 |

20 |

6 x 1.6 |

14 |

47 |

40 |

26.7 |

0.8 |

0.8 |

115 |

TSS 25 |

56 |

2200 |

1100 |

0.02 |

25 |

8 x 2.0 |

15 |

52 |

45 |

32 |

0.8 |

0.8 |

140 |

TSS 30 |

105 |

1800 |

900 |

0.03 |

30 |

8 x 2.0 |

16 |

62 |

55 |

40 |

0.8 |

1.0 |

215 |

TSS 35 |

136 |

1600 |

800 |

0.03 |

35 |

10 x 2.4 |

17 |

72 |

63 |

45 |

0.8 |

1.0 |

300 |

TSS 40 |

296 |

1400 |

700 |

0.18 |

40 |

12 x 2.2 |

18 |

80 |

72 |

50 |

0.8 |

1.0 |

425 |

TSS 45 |

347 |

1300 |

650 |

0.21 |

45 |

14 x 2.1 |

19 |

85 |

75.5 |

57 |

1.2 |

1.0 |

495 |

TSS 50 |

403 |

1200 |

600 |

0.22 |

50 |

14 x 2.1 |

20 |

90 |

82 |

62 |

1.2 |

1.0 |

545 |

TSS 60 |

649 |

910 |

460 |

0.33 |

60 |

18 x 2.3 |

22 |

110 |

100 |

80 |

1.2 |

1.5 |

950 |

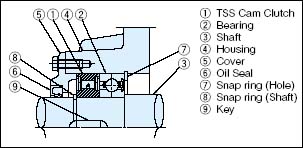

TSS -Series

Installation and Usage

- The TSS Series Cam Clutch is designed for press fit installation.

Correct interference dimensions must be maintained to obtain maximum clutch performance.

The internal diameter of the housing should meet the H7 tolerance. Refer to item 3 in the installation and usage of BB Series Cam Clutches for information on the installation method. - Make sure the housing has enough strength to withstand the pressure required for the press fitting installation of the clutch.

- When installing the clutch, mount it with a type 62 bearing to avoid radial force, since this clutch does not have any bearings inside.

- Confirm the direction of rotation before installation.

- The recommended shaft tolerance is H7, and the key profile should be in accordance with the following standard.

TSS 8 ~ 12............DIN 6885.1

TSS 15 ~ 60............DIN 6885.3 - Suitable surface pressure of the key should be selected according to your company design standards.

Lubrication

- Oil lubrication is recommended.

- Don not use greases or lubricants with EP additives.