>> MOUNTING AND REMOVAL

- Clean the inner surface of the hub bore and the shaft, and apply a slight amount of oil to both surfaces. (Do not use lubricants containing silicone or molybdenum disulfide.)

- Remove the locking bolts from the POWER-LOCK and clean and lightly oil, or grease the contact surface. Thread and seats of the tightening bolts must be sufficiently lubricated.

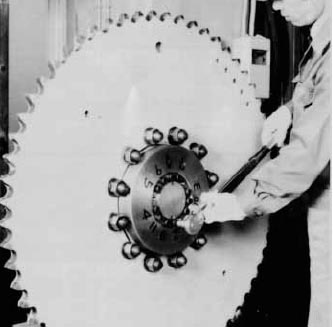

- Slip the POWER-LOCK and hub onto the shaft, tighten the locking bolts by hand until a slight positive contact is obtained and bring them to desired position. (Do not strike the POWER-LOCK with a hammer or other such tool during the mounting.)

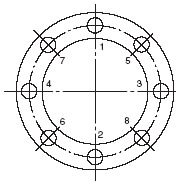

- Set a torque wrench to approximately 1/4 of the torque Ma (refer to the table given in each series specification) and thighten the locking bolts diagonally by torque wrench ( in the numerical order illustrated below).

- Raise the torque wrench setting to 1/2 of the torque Ma and repeat the procedure given in item 4 above.

- Raise the torque wrench setting to the full torque Ma and repeat the procedure given in step 4 above.

- Finally confirm that all locking bolts have been tightening to torque Ma. To do this, moving clockwise across the bolts, tighten each one until cannot be turned by the torque Ma.

Removal

- Make sure that there is no torque or thrust loads on the hub or shaft. Moreover, if the weight of the hub or shaft is very heavy or if a chain is installed, the removal procedure may become quite difficult. Remove the POWER-LOCK, only after preventing any problems that may occur due to these points. (When the tightening bolts are loosened, the POWER-LOCK may suddenly release and allow the device to spin or come off.)

- After ensuring safety, slowly loosen and remove the locking bolts.

- Remove hub and the POWER-LOCK from shaft.

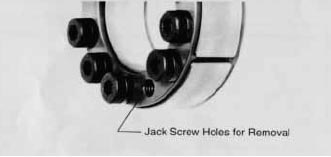

- If the POWER-LOCK still locks even after loosening bolts, apply a coat of oil to the threads of locking bolts and screw one bolt into each of the tapped holes for removal.