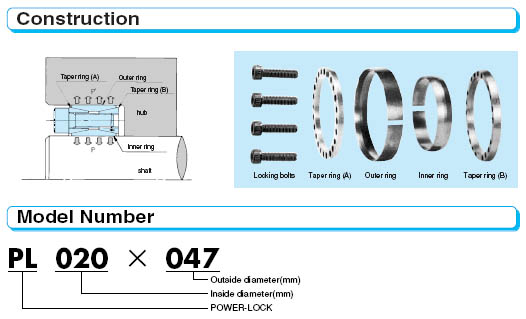

>> TSUBAKI POWER - LOCK AE Series

Features

-

Self - Centering Function

Straight and narrow hubs can be used with AE Series POWER-LOCK.

-

Interchangeable POWER-LOCK AS Series to AE Series

Have the same size inside diameter and outside diameter as POWER-LOCK AS Series.

-

Easy and Precise Positioning

-

Simple Construction

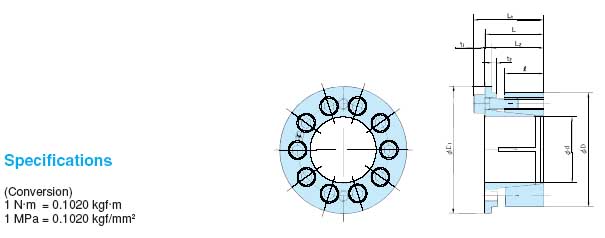

Specifications

(Conversion)

1 N.m = 0.1020 kgf.m

1 MPa = 0.1020 kgf/mm2

Model |

Dimensions (mm) |

Transmissible Torque |

Transmissible Thrust |

Contact Pressure (Mpa) |

Locking Bolts |

Mass |

||||||||||||||

d x D Inside Dia Outside Dia |

l |

L2 |

L |

Lt |

t1 |

t2 |

D1 |

Mt |

Pax |

Shaft P |

Hub bore P' |

Qty |

Size |

Tightening Torque Ma |

(kg) |

|||||

N-m |

{kgf-m} |

kN |

{kgf} |

MPa |

kgf/mm2 |

MPa |

kgf/mm2 |

N-m |

{kgf-m} |

|||||||||||

PL 019 x 047 AE |

19 |

24.8 |

27.3 |

33.3 |

2.5 |

3 |

53 |

265 |

{ 27} |

28.1 |

{2870} |

287 |

{29.3} |

93 |

{9.5} |

6 |

M6 x18 |

16.7 |

{1.7} |

0.28 |

PL 020 x 047 AE |

19 |

24.8 |

27.3 |

33.3 |

2.5 |

3 |

53 |

274 |

{ 28} |

28.1 |

{2870} |

272 |

{27.8} |

93 |

{9.5} |

6 |

M6 x18 |

16.7 |

{1.7} |

0.27 |

PL 022 x 047 AE |

19 |

24.8 |

27.3 |

33.3 |

2.5 |

3 |

53 |

304 |

{ 31} |

28.1 |

{2870} |

248 |

{25.3} |

93 |

{9.5} |

6 |

M6 x18 |

16.7 |

{1.7} |

0.26 |

PL 024 x 050 AE |

19 |

25.3 |

27.8 |

33.8 |

2.5 |

3 |

57 |

392 |

{ 40} |

32.8 |

{3350} |

274 |

{28.0} |

102 |

{10.4} |

7 |

M6 x18 |

16.7 |

{1.7} |

0.29 |

PL 025 x 050 AE |

19 |

25.3 |

27.8 |

33.8 |

2.5 |

3 |

57 |

412 |

{ 42} |

32.8 |

{3350} |

282 |

{28.8} |

102 |

{10.4} |

7 |

M6x18 |

16.7 |

{1.7} |

0.29 |

PL 028 x 055 AE |

19 |

25.3 |

28.6 |

34.6 |

3.3 |

3 |

62 |

519 |

{ 53} |

37.5 |

{3830} |

269 |

{27.4} |

106 |

{10.8} |

8 |

M6x18 |

16.7 |

{1.7} |

0.35 |

PL 030 x 055 AE |

19 |

25.3 |

28.6 |

34.6 |

3.3 |

3 |

62 |

559 |

{ 57} |

37.5 |

{3830} |

251 |

{25.6} |

106 |

{10.8} |

8 |

M6x18 |

16.7 |

{1.7} |

0.34 |

PL 032 x 060 AE |

20.5 |

27.3 |

30.9 |

36.9 |

3.6 |

3 |

67 |

745 |

{ 76} |

46.9 |

{4790} |

267 |

{27.2} |

113 |

{11.5} |

10 |

M6x18 |

16.7 |

{1.7} |

0.44 |

PL 035 x 060 AE |

20.5 |

27.3 |

30.9 |

36.9 |

3.6 |

3 |

67 |

823 |

{ 84} |

46.9 |

{4790} |

244 |

{24.9} |

113 |

{11.5} |

10 |

M6x18 |

16.7 |

{1.7} |

0.41 |

PL 038 x 065 AE |

20.5 |

27.5 |

31.1 |

37.1 |

3.6 |

3 |

73 |

892 |

{ 91} |

46.9 |

{4790} |

228 |

{23.3} |

104 |

{10.6} |

10 |

M6x18 |

16.7 |

{1.7} |

0.48 |

PL 040 x 065 AE |

20.5 |

27.5 |

31.1 |

37.1 |

3.6 |

3 |

73 |

931 |

{ 95} |

46.9 |

{4790} |

217 |

{22.1} |

104 |

{10.6} |

10 |

M6x18 |

16.7 |

{1.7} |

0.45 |

PL 042 x 075 AE |

23.5 |

30.8 |

34.8 |

42.8 |

4 |

3 |

83 |

1640 |

{ 167} |

78.1 |

{7970} |

285 |

{29.1} |

130 |

{13.3} |

9 |

M8x22 |

40.2 |

{4.1} |

0.76 |

PL 045 x 075 AE |

23.5 |

30.8 |

34.8 |

42.8 |

4 |

3 |

83 |

1750 |

{ 179} |

78.1 |

{7970} |

266 |

{27.1} |

130 |

{13.3} |

9 |

M8x22 |

40.2 |

{4.1} |

0.71 |

PL 048 x 080 AE |

23.5 |

31.0 |

35 |

43 |

4 |

3 |

88 |

2060 |

{ 210} |

86.8 |

{8860} |

280 |

{28.6} |

136 |

{13.9} |

10 |

M8x22 |

40.2 |

{4.1} |

0.81 |

PL 050 x 080 AE |

23.5 |

31.0 |

35 |

43 |

4 |

3 |

88 |

2160 |

{ 220} |

86.8 |

{8860} |

270 |

{27.5} |

136 |

{13.9} |

10 |

M8x22 |

40.2 |

{4.1} |

0.77 |

PL 055 x 085 AE |

23.5 |

30.8 |

34.8 |

42.8 |

4 |

3 |

94 |

2350 |

{240} |

86.8 |

{8860} |

242 |

{24.7} |

128 |

{13.1} |

10 |

M8x22 |

40.2 |

{4.1} |

0.84 |

PL 060 x 090 AE |

23.5 |

30.8 |

34.8 |

42.8 |

4 |

3 |

99 |

2550 |

{260} |

86.8 |

{8860} |

219 |

{22.3} |

122 |

{12.4} |

10 |

M8x22 |

40.2 |

{4.1} |

0.90 |

PL 065 x 095 AE |

23.5 |

30.8 |

34.8 |

42.8 |

4 |

3 |

104 |

3330 |

{340} |

104 |

{10600} |

246 |

{25.1} |

137 |

{14.0} |

12 |

M8x22 |

40.2 |

{4.1} |

0.96 |

PL 070 x 110 AE |

28 |

36.5 |

41 |

51 |

4.5 |

4 |

120 |

4800 |

{490} |

137 |

{14000} |

247 |

{25.2} |

132 |

{13.5} |

10 |

M10x25 |

81.3 |

{8.3} |

1.70 |

PL 075 x 115 AE |

28 |

36.5 |

41 |

51 |

4.5 |

4 |

125 |

5100 |

{520} |

137 |

{14000} |

230 |

{23.5} |

126 |

{12.9} |

10 |

M10x25 |

81.3 |

{8.3} |

1.79 |

PL 080 x 120 AE |

28 |

36.5 |

41 |

51 |

4.5 |

4 |

130 |

6570 |

{ 670} |

165 |

{16800} |

260 |

{26.5} |

145 |

{14.8} |

12 |

M10x25 |

81.3 |

{8.3} |

1.89 |

PL 085 x 125 AE |

28 |

36.5 |

41 |

51 |

4.5 |

4 |

135 |

6960 |

{ 710} |

165 |

{16800} |

244 |

{24.9} |

139 |

{14.2} |

12 |

M10x25 |

81.3 |

{8.3} |

1.98 |

PL 090 x 130 AE |

28 |

37.5 |

43 |

53 |

5.5 |

4 |

140 |

7450 |

{760} |

165 |

{16800} |

241 |

{24.6} |

134 |

{13.7} |

12 |

M10x25 |

81.3 |

{8.3} |

2.15 |

PL 095 x 135 AE |

28 |

37.5 |

43 |

53 |

5.5 |

4 |

145 |

9110 |

{930} |

193 |

{19700} |

267 |

{27.2} |

151 |

{15.4} |

14 |

M10x25 |

81.3 |

{8.3} |

2.24 |

PL 100 x 145 AE |

34 |

44.0 |

50 |

60 |

6 |

4 |

155 |

10300 |

{1050} |

207 |

{21100} |

218 |

{22.2} |

123 |

{12.6} |

15 |

M10x25 |

81.3 |

{8.3} |

3.07 |

PL 110 x 155 AE |

34 |

44.0 |

50 |

60 |

6 |

4 |

167 |

11400 |

{1160} |

207 |

{21100} |

198 |

{20.2} |

116 |

{11.8} |

15 |

M10x25 |

81.3 |

{8.3} |

3.35 |

PL 120 x 165 AE |

34 |

44.0 |

50 |

60 |

6 |

4 |

177 |

14900 |

{1520} |

248 |

{25300} |

218 |

{22.2} |

130 |

{13.3} |

18 |

M10x25 |

81.3 |

{8.3} |

3.59 |

PL 130 x 180 AE |

38 |

50.0 |

57 |

69 |

7 |

6 |

195 |

19600 |

{2000} |

301 |

{30700} |

214 |

{21.8} |

129 |

{13.2} |

15 |

M12x35 |

142 |

{14.5} |

5.04 |

PL 140 x 190 AE |

38 |

50.0 |

57 |

69 |

7 |

6 |

205 |

21100 |

{2150} |

301 |

{30700} |

198 |

{20.2} |

123 |

{12.6} |

15 |

M12x35 |

142 |

{14.5} |

5.38 |

PL 150 x 200 AE |

38 |

50.0 |

58 |

70 |

8 |

6 |

215 |

27000 |

{2760} |

361 |

{36800} |

221 |

{22.6} |

140 |

{14.3} |

18 |

M12x35 |

142 |

{14.5} |

5.81 |

Note :-

- Torque Mt in above table is shown in case of Pax=0 and thrust Pax is shown n case of Mt=0 When torque and thrust are applied calculate composite torque and compare it with Mt.

-

Contact pressure P and P' in the above table indicate mean value only.

These pressures will fluctuate from - 20% to +40% due to the variable friction component forces resulting from the locking bolts. Mt and Pax are calculated as minimum values.